solutions

Provide the latestand solutionstechnologyOur excellent service and high-quality products have alwaysbeen the reason why customers trust and choose us

Learn about our productsproduct

Our main products include sheet metal stamping parts, machined parts, precision metal and plastic components, molds and more, providing our clients with the latest technology and solutions for their requirements. Our customers come from various industries such as automotive, aerospace, electronics, medical equipment, instrumentation and others. Our outstanding service and high-quality products have always been the reasons why our clients trust and choose us.

ABOUT US

Borui precise is committed to providing high-quality, efficient and cost-effective machining solutions to a wide range of global industries. Our focus is to produce high-quality machining products and services with the latest technology to meet and exceed our customers' expectations.

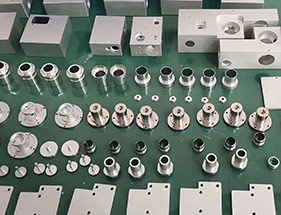

We specialize in precision machining and have a wide range of state-of-the-art CNC machines, including lathes, mills, laser marking machines and other advanced equipment. We are in compliance with international standards, providing accurate and stable products, ensuring the accuracy and quality of every single piece we produce.

We have all kinds of advanced CNC machine tools

With its efficient production, high accuracy, strong stability, complex shape processing capabilities and a wide range of application prospects, we have become an important support for the modern manufacturing industry. With the continuous progress of technology and the expansion of application fields, we will continue to provide high-quality products for various industries and promote technological innovation and industrial upgrading.

By providing turnkey rapid prototyping services, we have successfully helped many customers test and optimize their new products for defects, effectively reducing potential risks in the development phase, further reducing production costs, and improving overall project execution efficiency.

SERVICE

Advanced equipment and technology

CNC precision machining through the computer program to precisely control the trajectory of the tool and processing parameters, can control the error in a very small range. This high precision ensures dimensional accuracy and shape accuracy of parts, which is crucial for industries that require high precision. CNC machining also has the characteristics of high repeatability and stability, once the setting is completed, the machining process can be repeated countless times, and maintain stable processing quality. This not only helps to improve the overall reliability of the product, but also guarantees the quality consistency of each component in mass production.

Cope with a variety of complex shapes

Complex structures such as three-dimensional surfaces and special-shaped holes that are difficult to complete with traditional processing methods can be easily processed by CNC precision machining. For example, in the field of mold manufacturing, CNC machining can precisely produce injection molds with complex cavities to meet the molding needs of different products. CNC machining equipment has the functions of high-speed cutting and automatic tool change, which greatly reduces the processing time and improves the production efficiency. The multi-axis CNC machining center can also process multiple surfaces at the same time, further improving efficiency.

Provide high quality service and guarantee

The company has advanced five-axis machining technology and strict quality control system to ensure high precision and high stability of products. Provide customized services, design and manufacture products according to the specific needs of customers, so as to meet the individual needs of different customers. Professional technical team is one of the core competitiveness of precision machining company. They not only have extensive design experience, but also provide one-stop solutions for projects from design to delivery.

Professional after-sales service

Timely response to customer needs, to provide professional technical support, a full range of training services and high-quality after-sales service guarantee, with comprehensive service guarantee, become a trusted partner in the industry.

Cooperation process

Submit a document

Please submit your CAD file online and provide key information about the project so that we can provide you with an immediate quote.

Get a quote

We will provide a Design for Manufacturability (DFM) analysis and quotation free of charge, and recommend the best design improvements and processing techniques for your project.

Parts manufacturing

We provide a one-stop service to ensure the high quality of parts from production to delivery, ensuring high precision and high stability of products.

Product delivery

Custom manufactured parts will be shipped as soon as possible

blog

Advanced Techniques in Fancy Vacuum Silicone Casting for Precision Manufacturing

In the realm of manufacturing, particularly within the sectors of metalworking and casting, the pursuit of precision and quality is paramount. One advanced technique that is gaining traction is "fancy vacuum silicone casting." This method offers several benefits that can significantly enhance production outcomes. Fancy vacuum silicone casting involves using a silicone mold, created under vacuum co

Why Durable CNC Surface Finishing is Essential for Quality Manufacturing

Why Durable CNC Surface Finishing is Essential for Quality Manufacturing Table of Contents 1. Introduction to CNC Surface Finishing 2. The Importance of Durable CNC Surface Finishing 3. Key Benefits of CNC Surface Finishing 4. The CNC Surface Finishing Process Explained 5. Materials Commonly Used in CNC Surface Finishing 6. Applications of CNC Surface Finishing Across Indu

Exploring Advanced Non-Ferrous Machining Techniques in Precision Manufacturing

In the realm of manufacturing, particularly within non-ferrous machining, the focus is increasingly shifting towards advanced techniques that can improve both efficiency and precision. Non-ferrous machining refers to the processes involved in working with metals that do not contain significant amounts of iron, such as aluminum, copper, and titanium. These materials are known for their lightweight,

Contact us

If you are interested in our products and want to know more details, please leave a message here, we will get back to you as soon as possible.