Jul 29,2025

How CE Automated Machining Revolutionizes Precision in Mechanical Fabrication

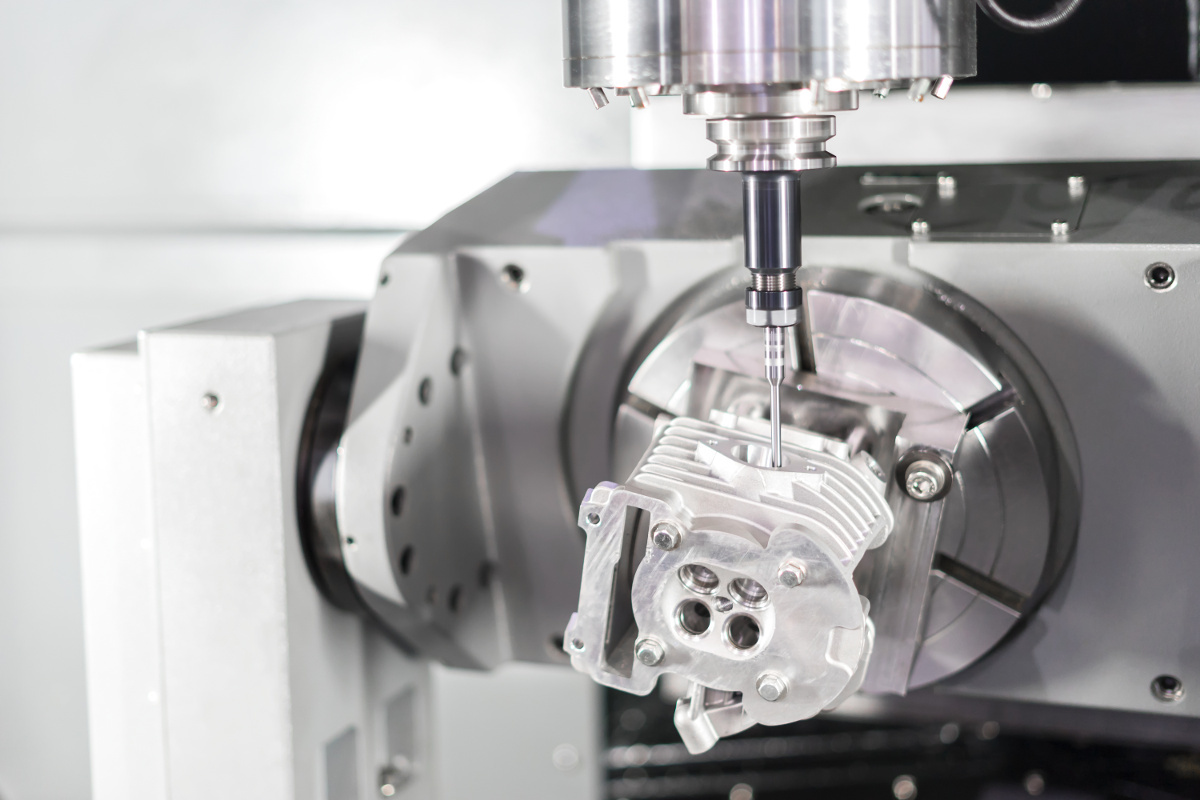

CE automated machining represents a significant advancement in the realm of mechanical fabrication. By providing unparalleled precision, efficiency, and cost savings, this technology is poised to revolutionize various industries

1. Introduction to CE Automated Machining

In today’s competitive manufacturing landscape, **CE automated machining** stands out as a transformative technology. This innovative approach leverages advanced machinery and software to enhance the precision and efficiency of mechanical fabrication processes. With the growing demand for accuracy in production, automated machining systems are becoming indispensable tools for manufacturers aiming to meet rigorous quality standards.

2. The Importance of Precision in Mechanical Fabrication

Precision is critical in mechanical fabrication, where even minor deviations can lead to significant performance issues and financial losses. High levels of accuracy ensure that parts fit correctly, operate efficiently, and maintain safety standards. CE automated machining delivers unparalleled precision, enabling manufacturers to produce components with tolerances that were previously unattainable, thereby safeguarding the integrity of the end products.

3. Key Features of CE Automated Machining

To fully appreciate the impact of CE automated machining, it is essential to understand its key features that contribute to enhanced precision and efficiency.

3.1 Advanced Control Systems

CE automated machining systems utilize sophisticated control systems that allow for real-time monitoring and adjustments. These systems enable machines to execute complex tasks with minimal human intervention, significantly reducing the likelihood of errors.

3.2 Integration of AI and Machine Learning

Artificial Intelligence (AI) and machine learning are integral components of modern automated machining. By analyzing vast amounts of data, these technologies optimize machining processes, predict maintenance needs, and enhance production schedules, resulting in improved precision and reduced downtime.

3.3 Enhanced Material Handling

The automation of material handling processes minimizes human error and maximizes efficiency. Automated loading and unloading systems ensure that materials are precisely positioned for machining, further increasing the accuracy of the fabrication process.

4. Benefits of CE Automated Machining

The adoption of CE automated machining brings numerous advantages that can significantly impact a manufacturing operation.

4.1 Improved Accuracy and Consistency

One of the most notable benefits of CE automated machining is its ability to deliver consistent results. Automated systems perform tasks with a level of precision that significantly reduces variability, leading to higher quality products.

4.2 Increased Production Efficiency

Automated machining systems operate at higher speeds than traditional methods, allowing manufacturers to increase output without compromising quality. This efficiency is particularly beneficial in high-demand industries where time-to-market is critical.

4.3 Cost Reduction and Waste Minimization

By enhancing precision and efficiency, CE automated machining helps manufacturers reduce production costs. Improved material utilization and decreased scrap rates directly translate to lower operational expenses.

5. Applications of CE Automated Machining in Various Industries

CE automated machining is revolutionizing multiple industries, each with its unique demands for precision and quality.

5.1 Aerospace and Defense

In the aerospace sector, where safety and reliability are paramount, CE automated machining ensures that components meet stringent specifications. The technology allows for the production of lightweight yet robust parts critical to aircraft performance.

5.2 Automotive Manufacturing

The automotive industry benefits from automation through the rapid production of high-precision components. CE automated machining facilitates the creation of intricate parts, enhancing vehicle performance and safety.

5.3 Medical Device Production

In medical manufacturing, precision is not just a preference but a necessity. Automated machining systems enable the creation of complex medical devices that adhere to strict regulatory standards, ensuring patient safety.

6. Challenges and Considerations

While the benefits of CE automated machining are clear, several challenges must be addressed for successful implementation.

6.1 Initial Investment vs. Long-Term Savings

The upfront costs associated with acquiring automated machining systems can be significant. However, manufacturers must consider the long-term savings generated through enhanced efficiency, reduced labor costs, and minimized waste.

6.2 Training and Workforce Adaptation

The transition to automated systems requires a skilled workforce capable of operating and maintaining advanced machinery. Investing in training programs is essential to ensure that employees can adapt effectively to these new technologies.

7. Future Trends in Automated Machining

The landscape of CE automated machining is rapidly evolving. Emerging trends include the incorporation of **Industry 4.0** principles, where smart factories leverage interconnected devices to streamline manufacturing processes further. Additionally, advancements in robotics and IoT (Internet of Things) will continue to enhance the capabilities of automated machining systems, making them more efficient and intelligent.

8. Conclusion

CE automated machining represents a significant advancement in the realm of mechanical fabrication. By providing unparalleled precision, efficiency, and cost savings, this technology is poised to revolutionize various industries. As manufacturers embrace automated machining, they will not only enhance their production capabilities but also drive innovation in product design and development, ultimately leading to a more robust and competitive marketplace.

Previous: None

Next: The Intricacies of Chinese Precision Parts in Manufacturing