Sep 10,2025

How Is CAD CAM Machining Transforming Modern Manufacturing

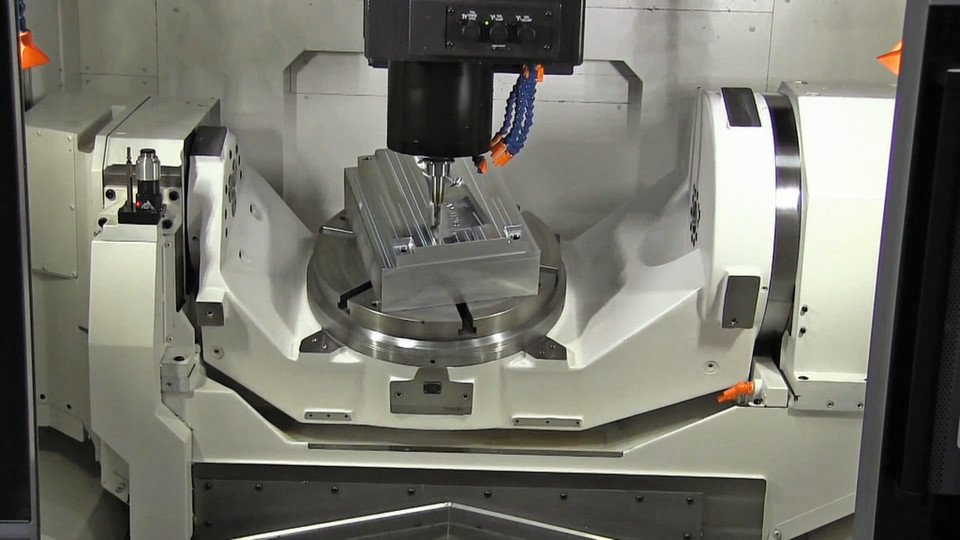

CAD CAM machining is revolutionizing the way manufacturers design and produce complex parts by merging digital design with automated production

CAD CAM machining is revolutionizing the way manufacturers design and produce complex parts by merging digital design with automated production. This approach integrates Computer-Aided Design (CAD) software, used to create detailed digital models, with Computer-Aided Manufacturing (CAM) software, which converts those models into precise machining instructions. The seamless link between virtual design and physical production eliminates manual data translation, ensuring greater accuracy, consistency, and speed throughout the entire manufacturing process.

By automating the workflow from concept to finished part, CAD CAM machining reduces the possibility of human error and accelerates production timelines. It allows intricate geometries to be created with high precision and repeatability, even on challenging materials. The system also enables real-time simulation, which helps engineers detect potential issues before production begins, saving time and resources. Its flexibility supports rapid design changes, efficient material usage, and streamlined multi-axis machining, making it a vital tool for modern precision manufacturing.

As industries continue to demand more complex components with tighter tolerances, CAD CAM machining is becoming increasingly essential. Ongoing advances in software intelligence, machine integration, and automation are expanding its capabilities, paving the way for smarter, faster, and more adaptive production methods. With its ability to bridge design innovation and high-precision fabrication, CAD CAM machining is set to remain a driving force in shaping the future of manufacturing technology.

Previous: What Makes Swiss Machining a Game-Changer in Precision Manufacturing

Next: None